Мені потрапили ось ці дві виделки. Абсолютно схожий дизайн з французськими відомими моделями. , що випускались до 1920-го року... Яким чином на виробах появились клейма Сілезії невідомо. Виделки покриті товстим слоєм срібла. Потрапили в Україну в часи другої світової війни...

MARKS OF FRENCH SILVER-PLATED CUTLERY IN THE XIXth CENTURY.

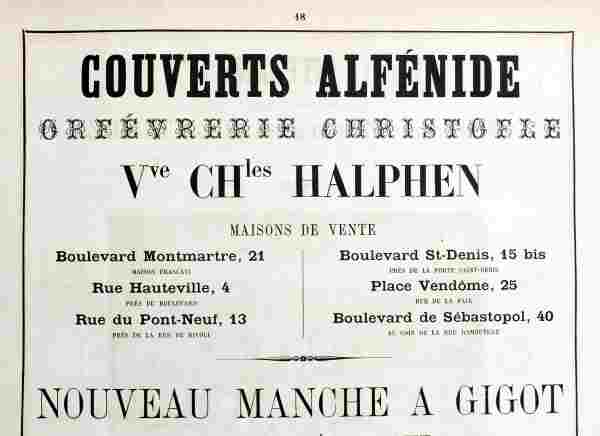

CHRISTOFLE , VEUVE CHARLES HALPHEN, GOMBAULT-DESCLERCS

& MANUFACTURE DE L'ALFÉNIDE

Christofle silver-plated cutlery.

So far I was not interested by the marks of silver-plated cutlery. However, the early pieces of Christofle cutlery seem to be remarkable. First of all, they are excellently designed. Second, they are convenient, beautiful and robust. Third, they are self-documented, as every piece is marked by its year of production. And, fourth, they are world-wide spread. It should be reminded that around 1844 the Christofle company pioneered the mass production of silver-plated cutlery and continued until at least 1930. As a result nowadays you can find Christofle cutlery from the XIXth century practically everywhere on the globe, in any antiques shop or on any flea market. In addition, many other French and foreign jewellery firms, producing silver-plated cutlery, copied the pieces of Christofle cutlery. I can easily mention a dozen of European jewellery firms, issuing silver-plated cutlery "ŕ la Christofle cutlery", amongst them the French firms Ercuis, Halphen, Desclercs, Frenais, the German companies WMF, August Wellner Soehne, Bohrmann, Hartmann, Henniger, the Austro-Hungarian factories Arthur Krupp Berndorf, Herrmann, the Russian foundries (situated in Warsaw) Fraget and Norblin and many others.

In this paper I will describe the marks used by Christofle and his partner companies Halphen, Gombault-Desclercs and Manufacture de L'Alfenide on spoons and forks during the XIXth century. Some of the marks are published for the first time. I had to omit the cutlery marks used on the knives as such pieces are rather rare and absent in my collection.

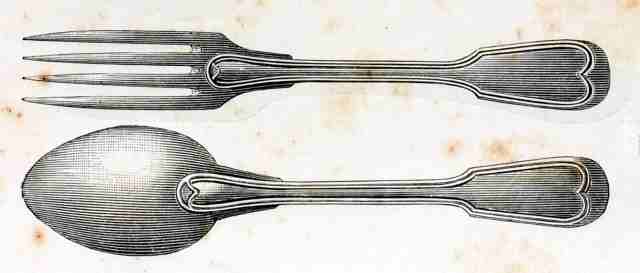

In Figure 1 one can see one of most successful (and popular) models from Christofle cutlery. It is a so-called "Filet" (or "Chinon") model. In Germany this model was known as "Augsburger Faden" and in England as "Fiddle & Thread". It should be noted that the same design was used in France well before the Christofle epoch, however, at that time it was produced from sterling silver and of course in much smaller quantities.

|

|

|

Fig.1. "Filet" (or "Chinon") model of Christofle cutlery. Above: a picture from the Manufacture |

The history of the Christofle jewellery firm is well documented [1,2]. Much less information is available on its partners Charles Halphen, Gombault-Desclercs and Manufacture de L'Alfénide.

Gombault-Desclercs, Charles Halphen and Manufacture de L'Alfénide firms.

From the technological point of view, all history of silver-plating is related to the research & development of a suitable base metal for silver deposition. In the beginning of the XIXth century it was the permanent search for a cheap silver-like base metal for silver deposition, the use of which would not change significantly the appearance of the product after the wearing away of the thin external silver layer. Such metal (nickel-copper-zinc alloy) was found in the twenties/thirties years of the XIXth century simultaneously in a number of European countries, with each inventor proposing its own slightly different composition of the alloy. The names of the alloys were also different (Argentan, Neusilber, Alpacca, etc.). The first patent for silver-like metal was given in France on 22nd of June 1827 to Maillot and Chorier for their alloy Maillechort (25% nickel, 50% copper and 25% zinc), invented as early as 1819.

Gombault, one of the oldest (and nearly forgotten!) French silver plate companies, was founded in 1826 [3]. This foundry pioneered the production of the so-called Gombault metal (a base metal for silver plating, i.e, a kind of nickel silver), which is a nickel-copper alloy with small additions of zinc, iron and tin [3]. Its mark for such non-silvered products, the inscription "GOMBAULT", was in use until 1931.

Some successful Gombault products, made from "highly-polished silver-like metal", included coffee-pots (cafetičres), hot chocolade pots (chocolatičres) and punch bowls (bols ŕ punch). But especially popular were the flat spoons with numerous holes (cuillers ŕ absinthe), used during the absinthe consumption for the so-called "fire ritual". First, the sugar cube saturated with absinthe was put on the spoon above the glass containing the absinthe drink. After that, the sugar cube was set on fire and started to melt into the absinthe, thus improving the bitter taste of the drink.

The Gombault firm also produced silver-plated tableware, but only in cooperation with other French silversmith companies. Its common partner for silver plating was the Desclercs company. Therefore, these two companies are often mentioned together as one entity, the so-called Maison Gombault-Desclercs (Gombault-Desclercs holding). For marking of such joint production both marks of Gombault (for marking the base metal) and Desclercs (for marking the silver deposition) were used. In 1866, the Gombault-Desclercs company became bankrupt and was absorbed by the Halphen firm. Later, being a part of the Veuve Charles Halphen (Widow of Charles Halphen) company, it still continued to use its own mark.

The Paris jewellery firm Halphen was created in 1850 by two brothers, Maurice and Charles Halphen [4]. After three years, Maurice Halphen left the business, and the firm was renamed as C. Halphen et Cie (Charles Halpen and Co.) with Charles Christofle being a principal shareholder. The main product of this enterprise was the silver-plated cutlery. As a base metal for silver-plating, home-made Alfénide metal, a copper-zinc-nickel-iron alloy (with component relative compositions of 59:30:10:1, respectively) was used. Clearly, the alloy name was derived from the name of the company owner. The Christofle firm was vitally interested in such cooperation as, up to 1878, it could not manufacture any silver-like metal for subsequent silvering and was forced to use brass as a base metal in most of its products.

Besides, since 1853, a new industrial process allowing the fabrication of huge series of cutlery pieces before the silvering, invented by Français Levallois, was applied on the Charles Haplhen foundry [1]. On the opposite, the Christofle's cutlery was made one by one. Since this new production method required a heavy financial investment, Christofle signed a special cooperation agreement with Halphen. According to this contract, Halphen and Christofle used the following production scheme: first Christofle designed the future objects, then Halphen mass-produced them from the Alfénide metal, after that the objects were silver-plated by Christofle, using the galvanic deposition of precious metal. The final product bore the Christofle mark of silvering, the inscription CHRISTOFLE, the box with the inscription ALFÉNIDE, indicating the base metal, and the box with the year of production. The Halphen company was not mentioned.

At the beginning the Halphen firm was rather successful. In 1866, Halphen bought the Maison Desclercs-Gombault. It is unknown when he died. Since around 1877 his firm was guided by the Veuve Charles Halphen (the widow of Charles Halphen, her exact name is also unknown). The name of Charles Halphen foundry was changed to "Couverts Alfénide, Orfévrerie Christofle et Veuve Charles Halphen" (Fig.2).

On 17 March 1877, the Veuve Charles Halphen registered the famous "tęte de bouc" (goat head) mark with the initials of her husband [5] and her factory, situated at 4, rue d'Hauteville, Paris, started its own production of the silver-plated hollowware of rather elaborated design. Over the next eleven years about 90,000 "large" hollowware items were to be manufactured, which corresponds to the mean productivity of 8,000 items per year. For comparison, the mean productivity of Christofle in the same time was about 6 times larger.

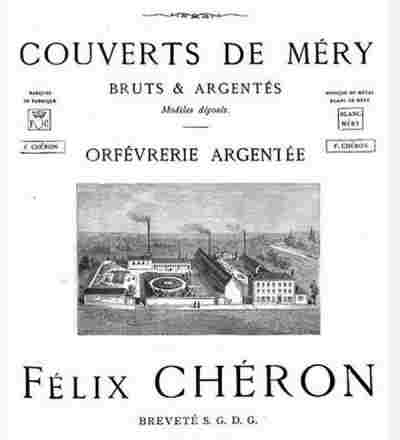

Meanwhile, in 1877, Christofle bought the bankrupt firm "Couverts de Méry", which produced its own base metal "Blanc Méry" (White Méry, named from Méry-sur-Oise, the place situated in the Seine-et-Oise region of France) with subsequent silver-plating, and hired the former boss of "Couverts de Méry", the talented jeweller and experienced manager Félix Chéron (Fig.3).

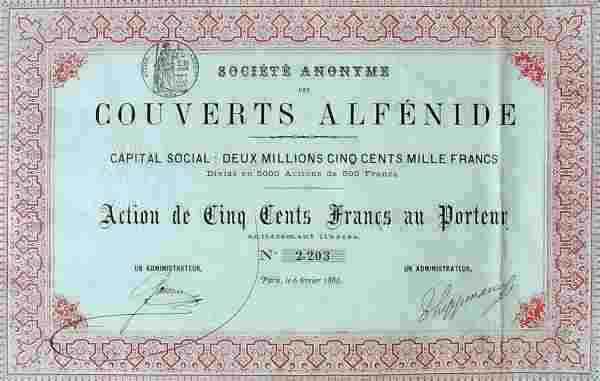

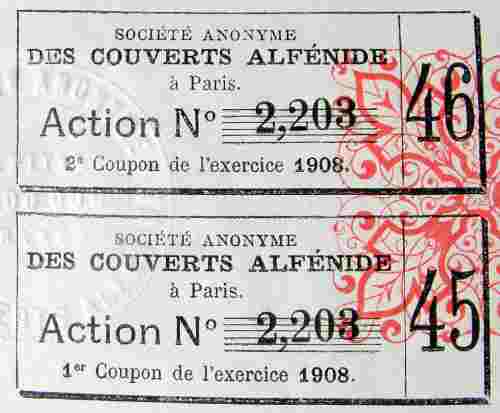

In 1878, Christofle opened a new giant factory in Saint-Denis near Paris (Usine de Saint-Denis) [1], which extracted nickel metal from the nickel ore brought from New Caledonia (Nouvelle Calédonie). This allowed Christofle to produce its own base metal for silver plating, called "Metal Blanc" (White Metal). The latter circumstance explains why, in the same year, Christofle broke its relations with Veuve Charles Halphen: there was no need for Alfénide after the development of its own silver-like metal. Meanwhile, the firm of Veuve Charles Halphen was transformed to "Société Anonyme des Couverts Alfénide" (sometimes before 1886) and corresponding shares were issued (Fig.4). However, such transformation did not save the company from bankruptcy.

|

|

Fig.4. Share No.2203 issued by the Société Anonyme des Couverts Alfénide on |

In 1888 Christofle bought the Halphen and Gombault-Desclercs companies. However, rather than integrating this acquisition, Christofle allowed it to continue as a separate entity. They were joined with the remains of "Couverts de Méry" firm under the new name "Manufacture de l'Alfénide" and with the new boss, the afore-mentioned Félix Chéron. This information is taken from the catalogue of Manufacture de L'Alfénide, issued in 1891 [7]. Though the name of Desclercs company is mentioned on the title list, no products of this firm are described in this catalogue. It follows that to that time the Desclercs company terminated fully its production.

Being inside the new firm, both Halphen and Gombault companies kept their own marks. However, under the patronage of Félix Chéron the Halphen's goat mark was slightly modified (the initials "C" and "H" for Charles Halphen were removed, and a part of the mark have been lined, see below) and used both for hollow ware and cutlery. What was even more unexpected was that the silver-plated hollow ware products made by "Manufacture de l'Alfénide" continued the original numbering introduced by Veuve Charles Halphen in 1877. Such ordinal numeration was kept going until 1931, the year of major restructuring inside the Christofle firm [2]. This finding allows the dating of each numerated silver-plated hollow ware item made by Veuve Charles Halphen, Gombault or Manufacture de l'Alfénide [8].

At the beginning of the XXth century Manufacture de L'Alfenide became extremely fashionable due to the appearance of new Art Nouveau products under the brand GALLIA. This brand inherited the above-mentioned Halphen's goat mark and used it until 1931 [8, 9].

Christofle cutlery marks used in the period 1845-1867 (silver-plated brass).

The silver-plated spoons and forks, issued between 1845 and 1867, possess three obligatory marks, set along the central part of the cutlery item (Fig.5).

|

|

Fig.5. Disposition of marks on silver-plated brass base Christofle cutlery pieces, |

We will describe these marks, starting from the one most distant from the handle:

1) The "CC" oval mark (Fig.6, above) contains four stars, two capital "C" letters (initials for "Charles Christofle"), between them a balance and a bee in the center above two palm-like branches. All mentioned elements are also characteristic for Christofle hollow ware products [2]. In the case of cutlery, the oval mark contains additionally a two-digit number (between the two plates of the balance), referring to the amount of silver (in grams), used for the production of two dozen pieces of cutlery. For the period 1845-1862, Christofle used 72 grams of silver for the silvering of 24 spoons (or 24 forks). It should be emphasized, that the mentioned amount refers only to standard serving forks and spoons, having around 21-22 cm in length. The silvering of smaller cutlery pieces (e.g., dessert forks and spoons and coffee/tea spoons) requests less silver. The mean size of the oval is 2.1 mm x 3.5 mm (for 20 different pieces of cutlery at my disposal, between 20.7 cm and 22.1 cm long).

According to new laws imposed by the French government, starting from 1862 the "CC" oval mark without the bee image (instead, a kind of rosette is used) is set inside a square box (Fig.7). The mean size of the rectangular box with the "CC" oval inside is 2.2 mm X 2.5 mm (for 3 different pieces of cutlery at my disposal, between 21.1 cm and 21.6 cm long). Simultaneously, the amount of silver, used for silvering of 24 spoons (or 24 forks), was increased up to 80 grams. Such an amount of silver was kept until 1868, when it was again increased to 84 g.

2) The year of production (two last digits) in the period 1845-1860 was set in a lozenge-shaped box (Fig.8). The mean size of the box (two diagonals), used between 1847 and 1859, is 2.2 mm x 3.4 mm (for 21 pieces of cutlery at my disposal). In 1860, a slightly different lozenge was used, its size is 1.6 mm x 3.1 mm.

In the same year (1860) another more serious change in marking the production year took place. Now instead of a lozenge-shaped box, a rectangular box was used (Fig.9). The mean size of this rectangular box is 1.6 mm x 1.9 mm (for four different pieces of cutlery at my disposal).

3) The mark of the firm, used in the period 1849-1862, is the inscription CHRISTOFLE set in a rectangular cartouche with rounded corners (Fig.10). The mean length of the inscription is 3.3 mm (for 17 different pieces of cutlery at my disposal). Attention! Sometimes on the early pieces the third mark is absent (e.g., on pieces issued in 1847 or 1850). Regarding four pieces of cutlery issued between 1860 and 1867 (at my disposal), it should be noted that the length of the CHRISTOFLE inscription varies between 3.2 and 3.5 mm and jumps to 4.5 mm in 1864.

Finishing this part of my investigation, it should be reminded that before 1855 all silver-plated cutlery pieces, produced by Christofle, used brass as base metal for silvering. In 1855 Christofle signed an agreement with Halphen and started to produce cutlery made from the silver-plated Alfénide metal. As a result the number of silverplated cutlery made from brass decreased drastically. Though 1862 Christofle catalogue still mentions the mark for silver-plated brass [6], it took me about a decade to find a fork, made from silver-plated brass and marked by 1867. How long Christofle company continued to use a brass base for silvering, I don't know, it is still an open question.

Christofle cutlery marks used in the period 1855-1877 (silver-plated Alfénide).

Marks used before 1862.

The silver-plated spoons and forks, issued by Christofle between 1855 and 1862, possess three obligatory marks (Fig.11).

|

Fig.11. Disposition of marks on silver-plated Alfénide base Christofle |

We will describe these marks, starting from the one most distant from the handle:

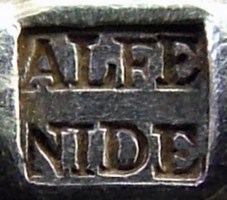

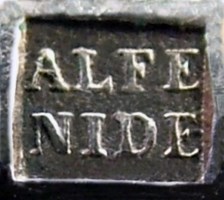

1) The lozenge-shaped box with the inscription ALFÉNIDE, on two lines (Fig.12), was used for the designation of the silver-like base metal. The mean size of the box (two diagonals) is 1.7 mm x 4.3 mm (for six different pieces of cutlery at my disposal);

2) The "CC" oval mark (Fig.13) corresponds to the one, used before c.1855 on Christofle silver-plated brass base pieces (see Fig.6). For the period between c.1855 and 1862, Christofle used again 72 grams of silver for the silvering of 24 standard spoons (or forks). The length of six spoons/forks at my disposal varies between 20.7 cm and 21.7 cm. The mean size of the oval is 2.0 mm x 3.6 mm (for four different pieces of cutlery);

3) For the time period c.1855-1859, the information about the production year (two last digits) was set in a lozenge-shaped box as above (Fig.14, above). The size of the box (two diagonals) is 2.1 mm x 3.5 mm (for two pieces of cutlery in my possession). Starting from 1860, Christofle used the rectangular box for this purpose (Fig.13, below) with size of 1.7 mm x 2.1 mm (for two pieces of cutlery at my disposal).

Fig.14. Marks used in 1862-1877 period.

From 1862, according to the new French government laws, some changes in cutlery marks were incorporated. Now the silver-plated spoons and forks, issued by Christofle, possess four obligatory marks (Fig.15).

|

Fig.15. Disposition of marks on silver-plated Alfénide base Christofle cutlery, |

We will describe these marks, starting from the one most distant from the handle:

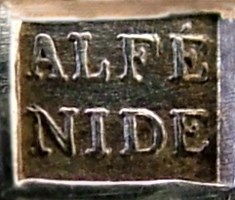

1) The rectangular box with the inscription ALFÉNIDE, on two lines, was used for the designation of the silver-like base metal (Fig.16). The mean size of the box with the inscription ALFÉNIDE is 1.7 mm x 2.4 mm (for 18 different pieces of cutlery at my disposal);

|

Fig.16. The box with the inscription ALFÉNIDE, used between 1862 and 1877. Note |

2) According to new laws imposed by the French government, the "CC" oval mark is now set in a square box, similar to the mark for silver-plated brass-based cutlery (see Fig.7). The bee image disappears, instead a rosette image is used (cf. Figs.11,15). This correlates with my earlier findings on marks of Christofle hollow ware [2]. In the case of ALFENIDE base, for the period between 1862 and 1868, Christofle used 80 grams of silver for the silvering of 24 spoons (or 24 forks). In 1868, the amount of silver used for the silvering of two dozen of pieces was raised to 84 grams (Fig.17). Again we mean the silvering of standard serving spoons or forks. In my collection there are 8 forks and spoons which were issued between 1862 and 1868 with the length of 20.6-21.7 cm. The mean size of the rectangular box (with the "CC" oval mark inside) in the above-mentioned period was 2.3 mm x 2.6 mm. I possess also 15 pieces of cutlery issued between 1868 and 1877 with the length of 20.5-21.5 cm. The mean size of the rectangular box (with the "CC" oval mark inside) for this time period is again 2.3 mm x 2.6 mm;

3) The information about the production year (two last digits) is placed in a rectangular box (Fig.18). The mean size of the rectangular box with two last digits of the production year is 1.6 mm x 1.8 mm (for 25 different pieces of cutlery at my disposal);

4) Finally, starting from 1865, Christofle adds to the cutlery marks of the products, made in a collaboration with Halphen, the inscription CHRISTOFLE in a cartouche (Fig.19). There were two types of the cartouche: rectangular with rounded corners (before 1874) or rectangular without rounded corners (in the period 1874-1877). It should be emphasized that a similar inscription was used previously (until at least 1867) while marking the Christofle cutlery, made from silver-plated brass (see above). The length of the inscription CHRISTOFLE is somewhat irregular: 3.3-3.4 mm in 1865 and 1868, 4.5-4.6 mm in 1865 and 1867, 4.9 mm in 1871, 5.2-5.3 mm in 1868 and 1873 and finally 7.1-7.5 mm in 1874, 1875, 1876 and 1877.

Christofle cutlery marks used in the period 1877-1899 (silver-plated Metal Blanc).

Since 1878, after breaking the relations with Veuve Charles Halphen company, Christofle produces the silver-plated cutlery using its own silver-like metal, called "Métal Blanc" (white metal). The designation for a base metal is absent. The other marks are similar to those used between 1874 and 1877 (Fig.20).

Fig.20. Disposition of marks on silver-plated Metal Blanc base cutlery pieces, issued by Christofle

in 1877 (above) and in 1886 (below). The handle is from the right side.

We will describe these marks, starting from the one most distant from the handle:

1) The "CC" oval mark in the square box (Fig.21) is similar to the one used between 1868 and 1877. The amount of silver used for the silvering of two dozen pieces is 84 grams. The length of 13 forks and spoons (at my disposal) issued in the period 1877-1899 varies between 20.7 cm and 21.4 cm. The mean size of the rectangular box (with the "CC" oval mark inside) is 2.3 mm x 2.5 mm (for ten different pieces of cutlery);

2) The information about the production year (two last digits) is placed in a rectangular box (Fig.22). The mean size of this box is 1.5 mm x 1.9 mm (for 13 different pieces of cutlery);

3) Finally, the inscription CHRISTOFLE in rectangular cartouche (Fig.23). The length of this inscription is quite irregular. In some years (1877, 1879, 1882, 1884, 1896, 1898 and 1899) it is about 6.0-6.1 mm. In other years (1883, 1885, 1886, 1895 and 1897) it fills the range of 7.3-7.5 mm.

|

Fig.23. The inscription CHRISTOFLE in rectangular cartouche, used on silver-plated Metal Blanc |

Halphen cutlery marks used in the period 1877-1885.

After Christofle had broken its relations with Halphen company (in 1867), which was guided by Charles Halphen's widow, the latter started to produce high-quality silver-plated cutlery under their own marks. The structure and disposition of these marks follow the structure and disposition of the ones used during the Christofle/Halphen cooperation in 1855-1877 (Fig.24, cf. Fig.15).

Fig.24. Disposition of marks on silver-plated Alfenide base cutlery pieces, issued by Veuve Charles

Halphen company: in 1878 (above), in 1881 (middle photo) and in 1885 (below).

The handle is from the right side.

We will describe these marks, starting from the one most distant from the handle:

1) The rectangular box with the inscription ALFÉNIDE in two lines (Fig.25) was used for the designation of the base metal. The mean size of the box is 1.7 mm x 2.2 mm (for seven different pieces of cutlery);

2) The famous goat's mark of Halphen (Fig.26) represents a goat's head in the rhombus with the initials "C" and "H" (Charles Halphen) from the left and right sides and number 84 under the head. The number 84 means that the amount of silver used for the silvering of two dozen pieces is 84 grams. The length of 7 forks and spoons (at my disposal) varies between 20.8 cm and 21.5 cm. The rhombus is placed inside the rectangular box. The mean size of the rectangular box is 2.1 mm x 2.5 mm (for six different pieces of cutlery);

3) The information about the production year (two last digits) is placed in a rectangular box (Fig.27). The mean size of the rectangular box with two last digits of the production year is 1.5 mm x 2.0 mm (for seven different pieces of cutlery);

4) Finally, the inscription HALPHEN in rectangular cartouche (Fig.28). The length of this inscription is 6.4-7.0 mm.

|

Fig.28. The inscription HALPHEN in rectangular cartouche used |

Manufacture de L'Alfenide cutlery marks used after 1890.

After 1890, Manufacture de L'Alfenide became a branch of the Christofle firm. However, for different reasons Christofle tried to hide this fact, and hence there was no mentioning of Christofle on the marks of cutlery used by the Manufacture de L'Alfénide. On the contrary, these marks are very similar to those used by Veuve Charles Halphen with some insignificant changes (Fig.29, cf.Fig.24).

|

Fig.29. Disposition of marks on silver-plated Alfénide base cutlery pieces, issued |

We will describe these marks, starting from the one most distant from the handle:

1) The rectangular box with the designation of the base metal ALFÉNIDE in two lines (Fig.30), is identical to that used by Christofle/Charles Halphen in 1862-1877 and Veuve Charles Halphen in 1878-1885 periods (Figs.16, 25). The mean size of the box is 1.8 mm x 2.1 mm (for five different pieces of cutlery);

|

Fig.30. The rectangular box with the inscription ALFÉNIDE, |

2) The Halphen goat's mark was slightly transformed (Fig.31). The initials "C" and "H" have been eliminated, instead of them from the left and right sides the digits "8" and "4" were set. The resulting number 84 meant that for the silvering of two dozen spoons (or forks) 84 grams of silver was needed. The length of 5 forks and spoons (at my disposal) varies between 21.1 cm and 21.8 cm. The rhombus with goat's head is placed inside the rectangular box, which is lined unlike the Halphen's goat mark (cf. Fig.26). The mean size of the rectangular box is 2.1 mm x 2.3 mm (for five different pieces of cutlery);

3) The information about the production year is absent. The inscription HALPHEN is given as before in a rectangular cartouche (Fig.32). The length of this inscription is 5.8-5.9 mm.

From the discussed material it follows that despite rather complicated relations between Christofle and its partners, the marks of silver-plated cutlery of these companies are related to each other and should be considered together. I believe that such studies will allow us to understand better the marking of other French silversmith companies in the XIX century and thus could be useful for future research in this area of art history.

The author is grateful to his wife Danielle for her continuous support.

Комментариев нет:

Отправить комментарий